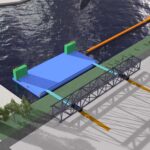

The Floating Docking Platform is a project introducing an innovative service to the market for transferring large-size floating and hydrotechnical (offshore) structures from land to water and from water to land, using automated computational algorithms.

The transport process will be carried out on modular SPMT (Self-Propelled Modular Transporter) platforms. A self-propelled modular transporter is a special vehicle equipped with hydraulically controlled steering and hydraulically controlled lifting.

Thanks to the high lifting capacity of the FDP (3,000–5,000 tons), the transported structures can be fully outfitted, e.g. ships or other fully equipped large-size structural and technological modules.

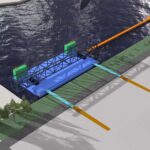

Naciski/obciążenie jednostkowe na polskich nabrzeżach portowych wynoszą 2,0 t/m2, dlatego zaprojektowana została specjalna kładka/pomost, która będzie służyć do transportu wielkogabarytowych konstrukcji o masie 3000 ton nad częścią nabrzeża

The total time for transport from the quay to the FDP and launching will be 5 hours for a vessel weighing 1,200 tons – compared to up to 48 hours with current methods.

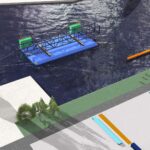

The length of an object that can be side-loaded onto the FDP after dismantling the towers is at least 90 m.